Discover the Cutting-Edge Innovations at the 2023 ChinaPlas Exhibition: Unveiling the Latest Breakthroughs in Arkpeek!

With the upgrading and transformation of China’s manufacturing industry, the demand for new materials and advanced technologies is expected to continue rising. The 2023 ChinaPlas Exhibition has witnessed impressive achievements in Arkpeek, showcasing a constant stream of PEEK innovations. In this article, PEEKCHINA will share some notable accomplishments in the field of specialty plastics.

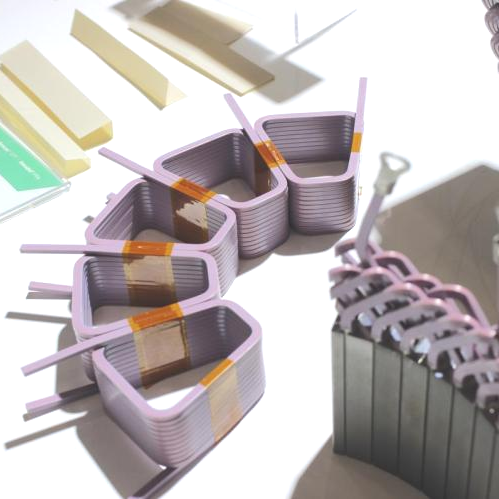

1, PEEK Flat Wire for New Energy Vehicle Motor

In new energy electric vehicles, electrical safety is of paramount importance. Choosing excellent materials is the key to ensuring the safe operation of new energy vehicles. PEEK (Polyether Ether Ketone) material can be regarded as a “hexagonal warrior” in the field of specialty engineering materials due to its outstanding properties such as corrosion resistance, wear resistance, high strength, and low density. It is particularly suitable for manufacturing durable components, prolonging the service life of parts, reducing maintenance frequency, and lowering costs. PEEK is increasingly replacing traditional metal materials such as aluminum, titanium, and steel in the construction of new energy electric vehicles, as well as in bearing and gear components. PEEK exhibits excellent resistance to electrical tracking, low dielectric constant, outstanding bending resistance, chemical resistance (including lubricating oil, ATF oil, impregnating paint, epoxy resin paint), and resistance to high and low-temperature conditions. It is an ideal choice for electric motors in new energy vehicles.

2, Medical Grade Implantable PEEK Material

As the name suggests, PEEK materials used for the preparation of “implantable instruments” are called medical-grade implantable PEEK. These materials are commonly used in orthopedic implant consumables (such as intervertebral fusion devices, ligament repair anchors, and joint interface screws), neurosurgery patches (such as artificial skull bones and craniofacial bones), and cardiovascular products (such as heart valve prostheses and pacemaker casings). In recent years, some manufacturers have been using modified PEEK materials for the production of high mechanical performance products, such as dental implants and trauma bone plates. In addition to meeting the biocompatibility requirements of ordinary medical-grade PEEK, implantable PEEK should also meet stricter requirements for biocompatibility, including systemic toxicity, genetic toxicity, carcinogenicity, blood compatibility, and implant reactions, in accordance with the specifications of “YY/T 0660 Surgical Implants — Polyether Ether Ketone (PEEK) Polymers”.

ARKPEEK’s registered ARK-BioPEEK® series of implantable PEEK materials have passed all the testing requirements of YY/T 0660–2008 and have obtained third-party test reports.

3, PEEK Motor Rotor Reinforcement Sleeve

Advantages:

a, Lightweight and ultra-high strength to achieve lightweight design.

b, Resistance to chemical media environment inside the motor.

c, Excellent fatigue resistance.

4, PEEK Film

PEEK film exhibits high heat resistance, good electrical and mechanical properties, with a continuous operating temperature of up to 240°C, low dielectric loss ranging from 0.001 to 0.003, and a transparency rate of up to 85.9%. Particularly outstanding are its resistance to chemical agents, hydrolysis, and radiation, which are prominent even among high-performance films.

5, CF/PEEK Composite Thin Sheet (CCM Method)

The CCM method utilizes continuous compression molding, which offers high and stable production efficiency. It can also produce shaped parts continuously, demonstrating advanced processing techniques.

6, CF/PEEK Composite Thick Plate

Continuous carbon fiber CF/PEEK thermoplastic composite plates are characterized by their low weight, high temperature resistance, resistance to humidity and heat, impact resistance, good dimensional stability, high fatigue strength, X-ray transparency, and biocompatibility. They are an optimal alternative to metal materials in the medical, aerospace, and defense industries.

7, CNT Modified PEEK

Carbon nanotube materials: Semiconductor conductive and antistatic materials that do not contain sulfur or precipitates. They have a high degree of cleanliness during formation, low surface reflectivity, stable conductive performance, low density, and recyclability.

8, Zeolite Membrane Dehydration Technology

This technology utilizes low-temperature, low-pressure dehydration techniques to manufacture creative products for separating medicinal ingredients. It improves esterification reaction efficiency, enhances conversion rate, product yield, and reduces raw material consumption.

9, PEEK Stator and Rotor Insulation

Slot liner and insulation slot wedge PEEK offers excellent voltage resistance, thermal conductivity, and temperature resistance. It can withstand ATF oil and bending stress during molding and processing.

10, Size 30*30mm PEEK Board Featuring 4,000 micro-holes.

11, PEEK Surgical Robot Components

Value proposition:

- Biocompatible color matching.

- Excellent dimensional stability.